System Selection for Engineering, Procurement and Construction Management Client

System Selection & Implementation

Overview

Our client is an engineering and construction company primarily serving the oil and gas industry. Providing their customers with turnkey solutions, the client performs both engineering and construction management to ensure a quality build for their customers.

Challenge

The client’s business had evolved from offering pure Engineering into offering Engineering, Procurement, and Construction Management (EPC), and the procurement and construction management side experienced rapid growth. While adjusting to the rapid growth on the EPC side of their business, the client recognized that the procurement system originally implemented to support engineering projects was not robust enough to support complex procurement and construction management needs. Given the limitations, the client implemented manual workarounds outside of the procurement system to keep track of the thousands of unique SKUs, tens of thousands of parts, and many sub-contracting companies used for each EPC project.

In search of a new Procurement and Inventory system, the internal procurement team was tasked to select a new tool. After a year of searching when time was available, the client still lacked clarity on which system to choose. The team was overwhelmed with options, unsure how to communicate to vendors what they needed, and unable to identify a best fit based on vendor-run product demos. Eventually the manual workarounds ran into “simple human mistakes” that resulted in multi-million dollar overspends and even more in lost opportunity costs. With these impacts, the client realized they lacked the time and methodology to do a thorough system selection, waiting for internal resources to solve the problem in their spare time was no longer an option, and specialized help was required.

Strategy

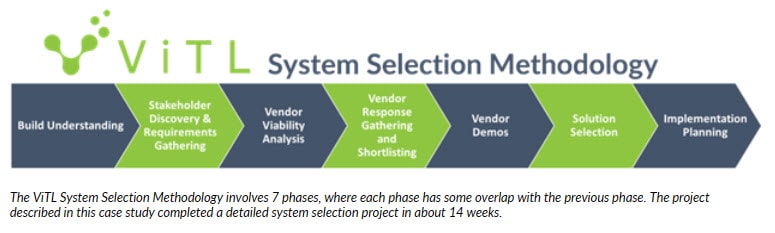

Recognizing the advantages of a specialized partner, the client engaged ViTL Solutions. A ViTL System Selection Lead was brought in to provide expertise and drive the effort under the overall direction of the client’s President and their Vice President of Projects. To keep costs low, the client assigned an internal resource as the project’s Business Analyst and quickly notified internal stakeholders that their involvement would be required. The project kickoff was co-led by ViTL and the project’s executive sponsor who together educated all involved employees on ViTL’s System Selection Methodology and the importance of stakeholder involvement to achieve proper system selection.

Execution

Following ViTL’s System Selection Methodology, the project kickoff was promptly followed by stakeholder meetings to define requirements and document current state processes. In parallel, vendor viability analysis was conducted to identify prospect software vendors. The requirements and current state processes were packaged with a Request For Proposal (RFP) and sent to vendors. Upon receiving the RFP, vendors self-evaluated whether they would be a good fit. Some vendors appropriately opted out, knowing they could not meet the client’s requirements – a time saving benefit for both vendors and the client.

Based on RFP responses, vendors were then invited to provide a multi-day live interactive demo on their ability to accommodate the client’s use cases and meet the client’s requirements. This enabled the client to see the system in action, score each vendor, and do a detailed side by side comparison of each vendor’s system capabilities.

Outcome

With RFP responses, pricing, and demos complete, the client was able to determine the best system for their organization. With quotes in hand, they were able to negotiate from a position of strength and achieve significant long term contractual savings of about $50K per year (a 12% reduction in price). By doing the upfront leg work of system selection (engaged stakeholders, current state processes mapped, requirements well defined), the client was able to go into system implementation with a head start and save on system implementation costs. Overall, the investment in system selection enabled savings by reduced contract costs and reduced time in the planning and designing phases of implementation. The project Return on Investment is expected to occur within one year of implementation completion.